woer

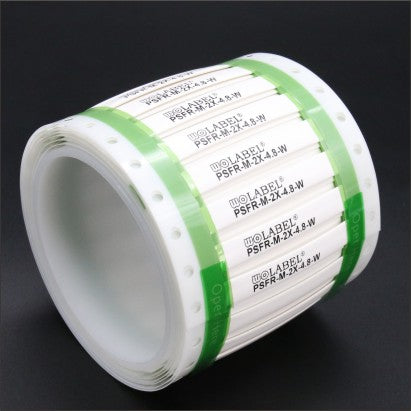

PSFR—High Temperature Heat Shrink Labeling Tube

PSFR—High Temperature Heat Shrink Labeling Tube

Couldn't load pickup availability

Application areas:

Fields such as rail transit, communications, and precision instruments.

Product Description

Heat shrink ratio: 2:1

Complete shrinkage temperature: ≥ +150 ° C

Operating temperature: -55°C to +225°C

Extremely high continuous operating temperature

Excellent oil resistance and low vacuum volatility

Environmental Standards: RoHS

Standard colors: yellow, white (other colors can be customized)

Product Parameters

|

performance |

index |

Test methods |

|

|

Physical properties |

size |

According to customer needs |

ASTM D 2671 |

|

Longitudinal length variation |

-10%~5% |

ASTM D 2671 |

|

|

Tensile strength |

≥24.1 MPa |

ASTM D 2671 |

|

|

Elongation at break |

≥300% |

ASTM D 2671 |

|

|

Wall deviation rate |

≤40% |

AMS-DTL-23053 |

|

|

secant modulus |

≥172 MPa |

ASTM D 2671 |

|

|

density |

≤1.9 g/ cm³ |

ASTM D 2671 |

|

|

Low temperature flexibility |

No cracks |

AMS-DTL-23053 (-55 ℃ ×4h) |

|

|

thermal shock |

No dripping, no flowing, no cracking |

ASTM D 2671 (250 ℃ × 4h) |

|

|

Tensile strength after heat aging |

≥19.1 MPa |

ASTM D 2671 (225 °C × 168h) |

|

|

Elongation at break after heat aging |

≥200% |

ASTM D 2671 (225 °C × 168h) |

|

|

Transparency stability |

Identifiable internal markings |

AMS-DTL-23053 (200 ℃ ×24h) |

|

|

Electrical insulation performance |

Dielectric strength |

≥15.7kV/mm |

ASTM D 2671 |

|

Volume resistivity |

≥10 12 Ω·cm |

ASTM D 2671 |

|

|

Chemical properties |

Copper corrosion |

Non-corrosive |

ASTM D 2671 (160 ℃ × 16h) |

|

Flame retardant |

Self-extinguishing within 60 seconds , with the paper flag burned to less than 25% damage. |

UL224 VW-1 , ASTM D 2671 Method C |

|

|

Water absorption rate |

≤0.5% |

ISO 846 B Law |

|

|

Tensile strength after mold resistance |

≥24.1 MPa |

ASTM D 2671 |

|

|

Elongation at break after mold resistance |

≥300% |

ASTM D 2671 |

|

|

Dielectric strength after mold resistance |

≥15.7kV/mm |

ASTM D 2671 |

|

|

Tensile strength after chemical resistance |

≥13.8 MPa |

ASTM D 2671 |

|

|

Elongation at break after chemical resistance |

≥200% |

ASTM D 2671 |

|

|

Dielectric strength after chemical resistance |

≥15.7kV/mm |

ASTM D 2671 |

Product Selection

|

Order Code |

Supply inner diameter (mm) |

Fully shrunk dimensions (mm) |

|

|

inner diameter |

Wall thickness |

||

|

PSFR-M-2X-1.2-* |

≥1.2 |

≤0.6 |

0.25±0.05 |

|

PSFR-M-2X-1.6-* |

≥1.6 |

≤0.8 |

0.25±0.05 |

|

PSFR-M-2X-2.4-* |

≥2.4 |

≤1.2 |

0.25±0.05 |

|

PSFR-M-2X-3.2-* |

≥3.2 |

≤1.6 |

0.25±0.05 |

|

PSFR-M-2X-4.8-* |

≥4.8 |

≤2.4 |

0.25±0.05 |

|

PSFR-M-2X-6.4-* |

≥6.4 |

≤3.2 |

0.30±0.08 |

|

PSFR-M-2X-9.5-* |

≥9.5 |

≤4.8 |

0.30±0.08 |

|

PSFR-M-2X-12.7-* |

≥12.7 |

≤6.4 |

0.30±0.08 |

|

PSFR-M-2X-19.1-* |

≥19.1 |

≤9.5 |

0.43±0.08 |

|

PSFR-M-2X-25.4-* |

≥25.4 |

≤12.7 |

0.48±0.08 |

|

PSFR-M-2X-38.1-* |

≥38.1 |

≤19.1 |

0.60±0.10 |

Note: "*" indicates a non-standard sleeve, manufactured according to order requirements.

Share